Nondestructive Testing

Nondestructive Testing

Nondestructive Testing (NDT)

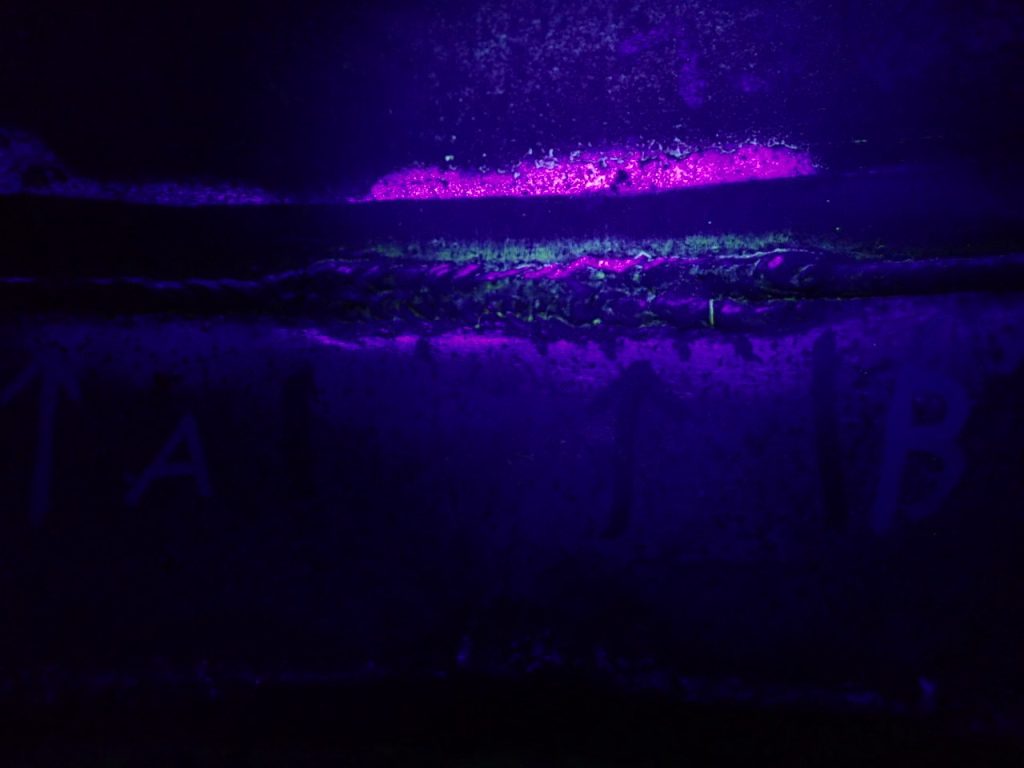

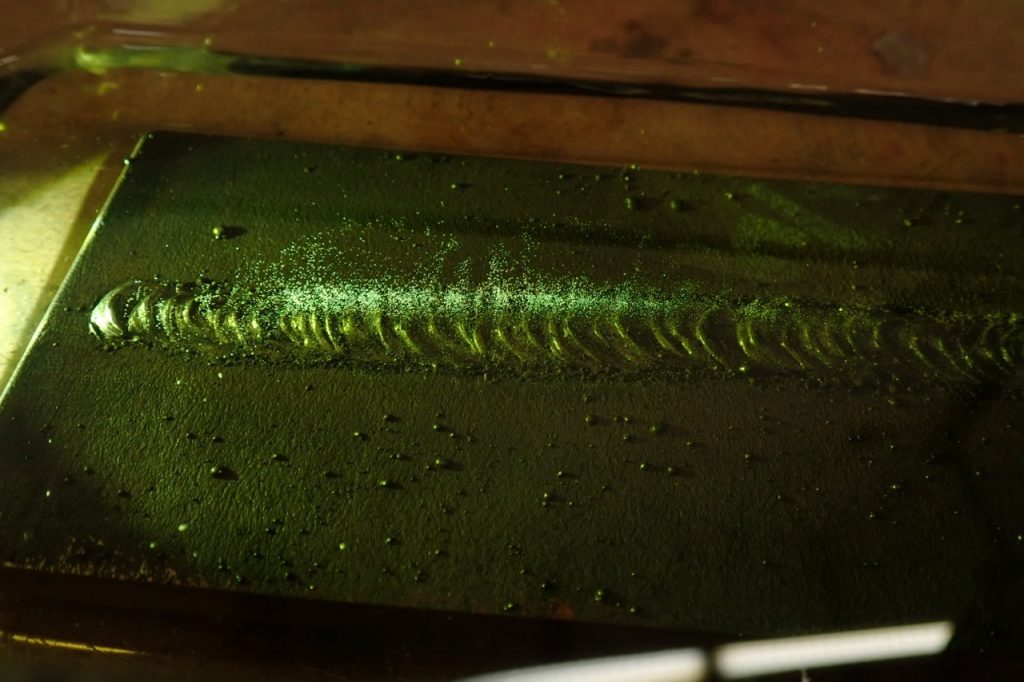

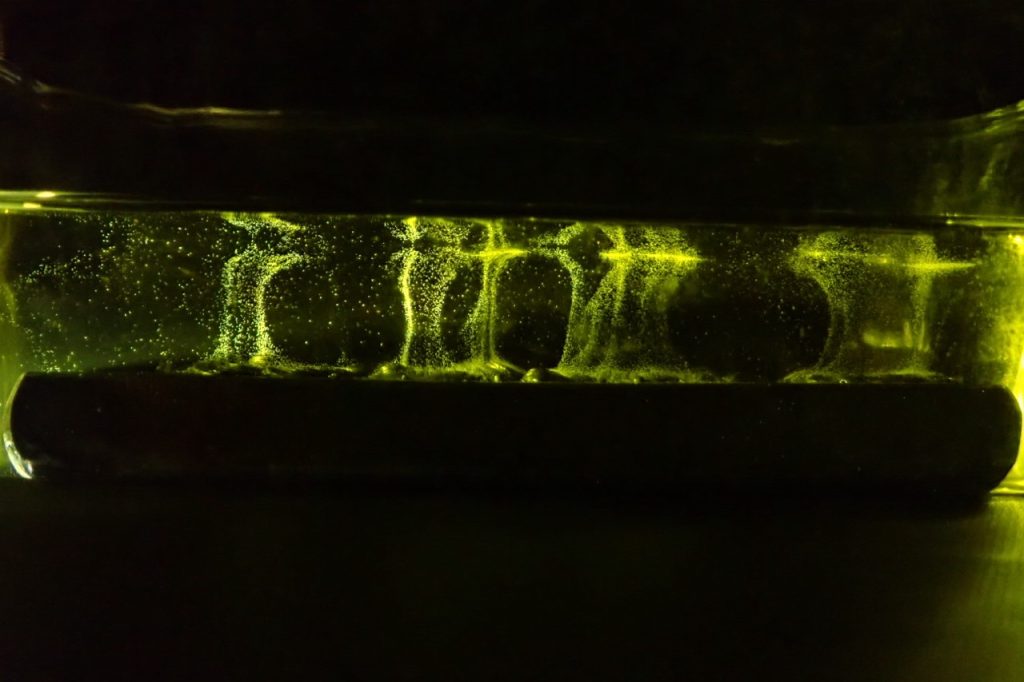

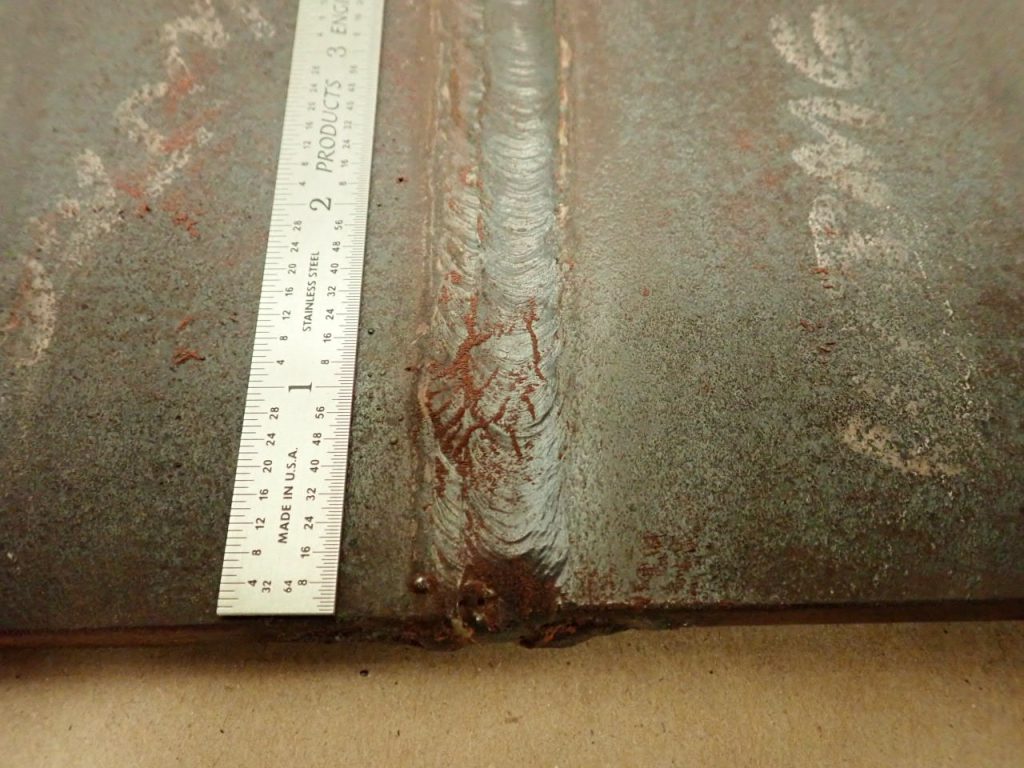

Our Newly redesigned NDT Lab is fully stocked and equipped to perform Magnetic Particle (MT) Dye Penetrant (PT) Ultra-sonic (UT) and X-ray Fluorescence (XRF) testing on small and medium sized parts of any volume.

We also provide Level I & II training under a Level III in accordance with your written practice.

Nondestructive Tests (ASNT, MIL-STDs):

NDT or Nondestructive testing can be performed using procedures and instruments that do not affect the future usefulness of the object or material. NDT allows parts and materials to be inspected, measured and analyzed without damaging or altering them. Because it allows inspection without interfering with a product’s final use, NDT provides an excellent balance between quality control and cost-effectiveness.

Our testing is done in-house, in our own independent testing laboratory over seen by not only an AWS CWI, but also an ASNT Level III P.E. WJMG strives for the most complete and comprehensive reporting when it comes to the materials being inspected.

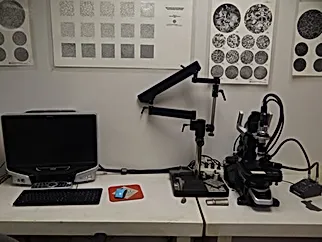

Digital Microphotography & SEM Services

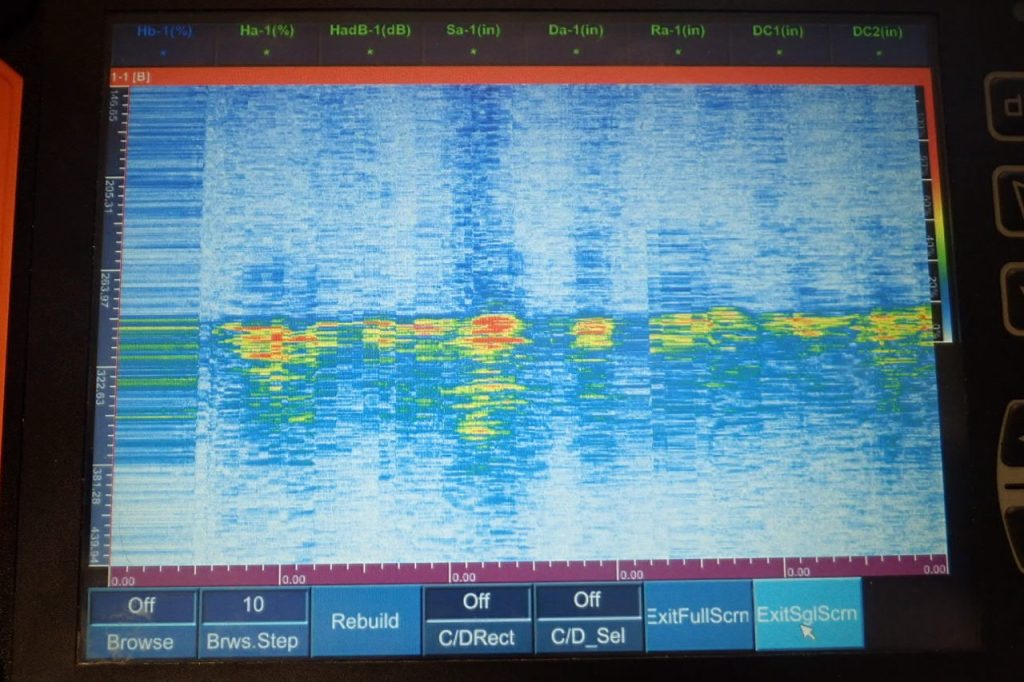

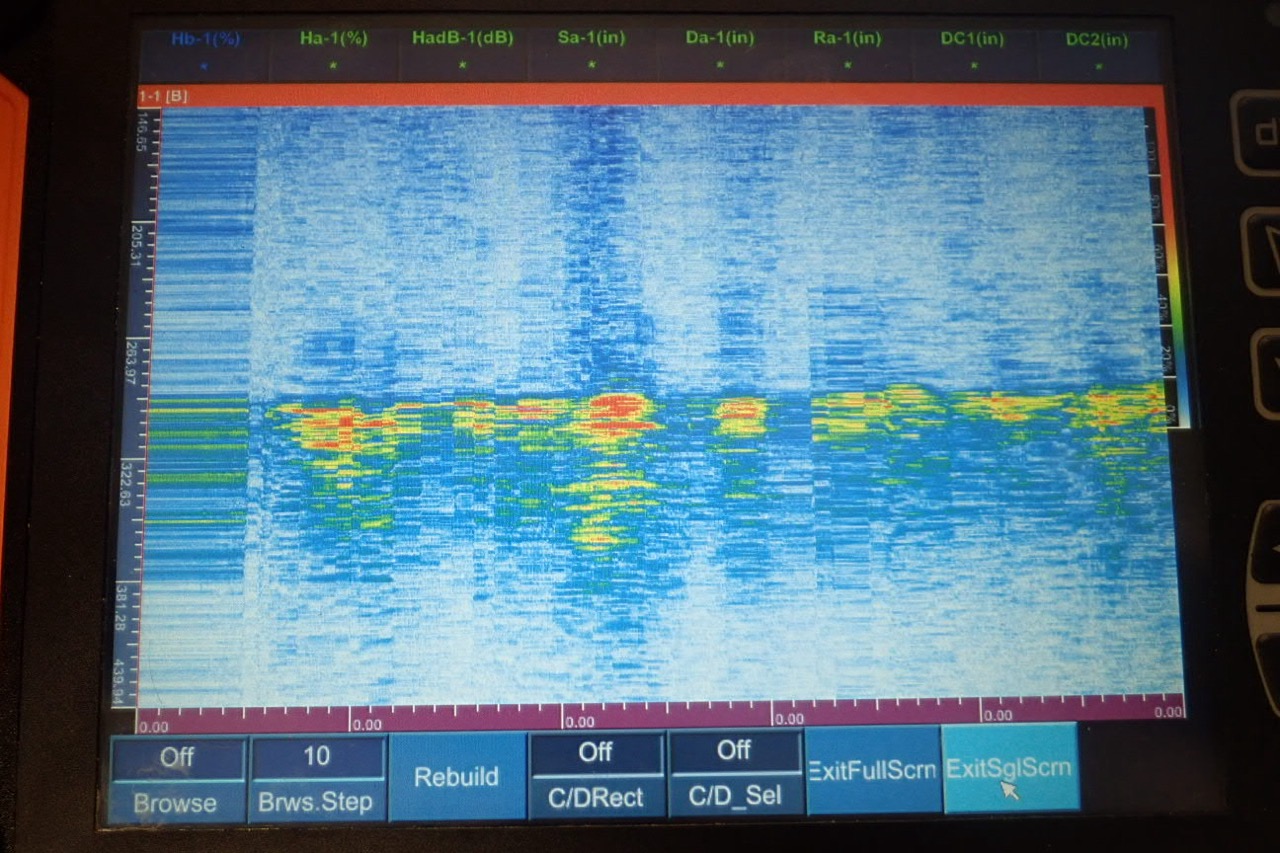

Our Keyance VHX 1000 Digital microscope and our new Scanning Electron Microscope are the flagships of our microphotography department.

The Keyence microscope is an effective forensic examination tool and allows us to offer extremely detailed measurements, three dimensional (3D) renderings and high definition images of welds and defects, all at magnifications up to 200X.

And the Scanning Electron Microscope (SEM) can analyze at a greater level than ever before. With magnifications up to 200,000X, we can detect issues in the materials as well as potential issue in joined materials that could result in failed welds.

NitonXRF

Our Niton X-Ray Fluorescence analyzer allows us to determine a specimen’s chemical composition without destroying it.

This unit is very useful for verifying material compatibility of equipment tools that are larger or not readily portable.