Keyence Microscope

Keyence Microscope

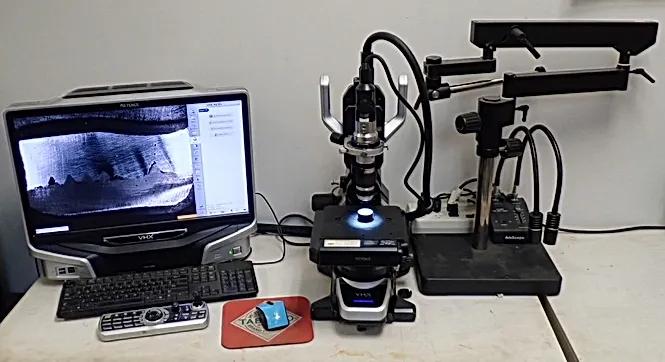

At Welding & Joining Management Group (WJMG), precision and clarity are central to our forensic and metallurgical services. To support our mission, we proudly utilize the Keyence Microscope, specifically the advanced Keyence 5000 digital microscope system (Model VHX-5000). This high-performance tool allows us to deliver accurate, high-resolution imaging and detailed documentation for a wide range of materials and surfaces.

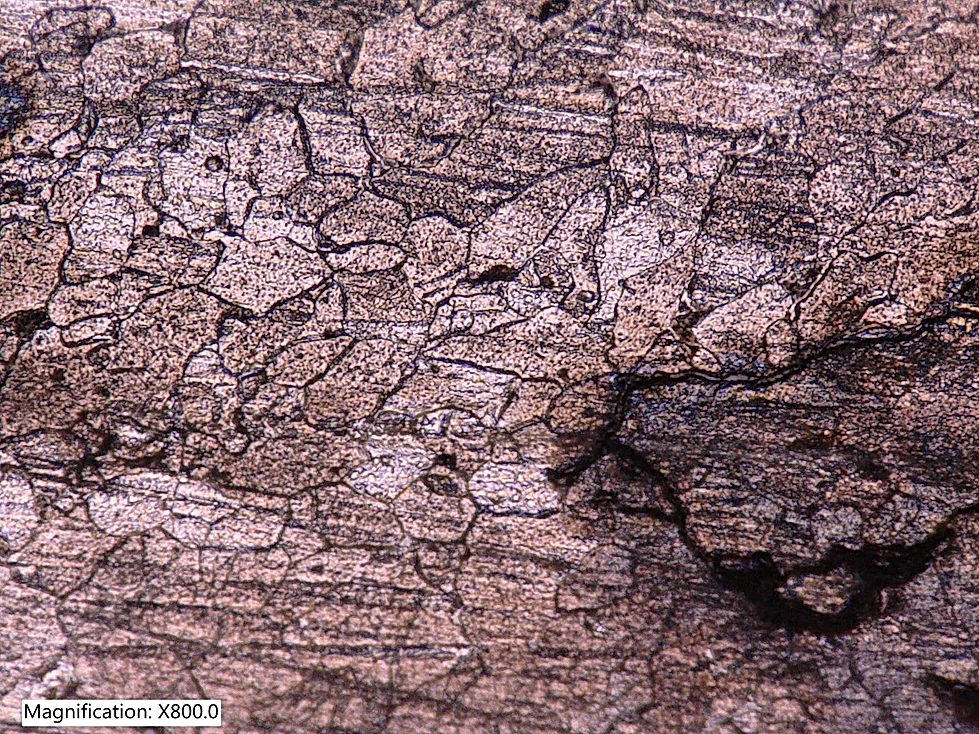

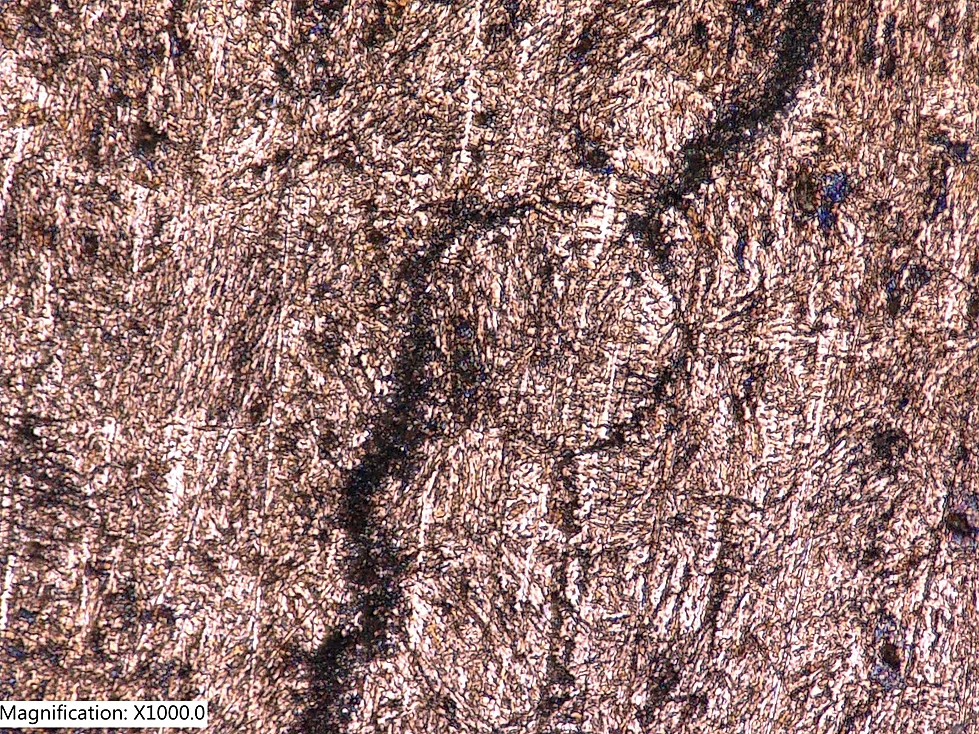

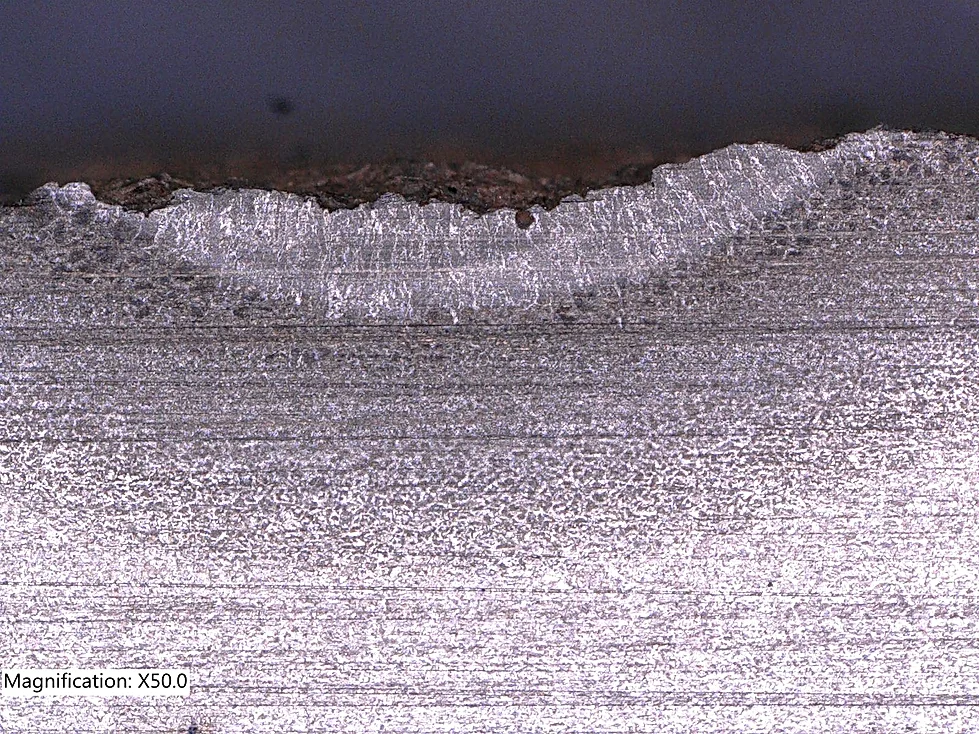

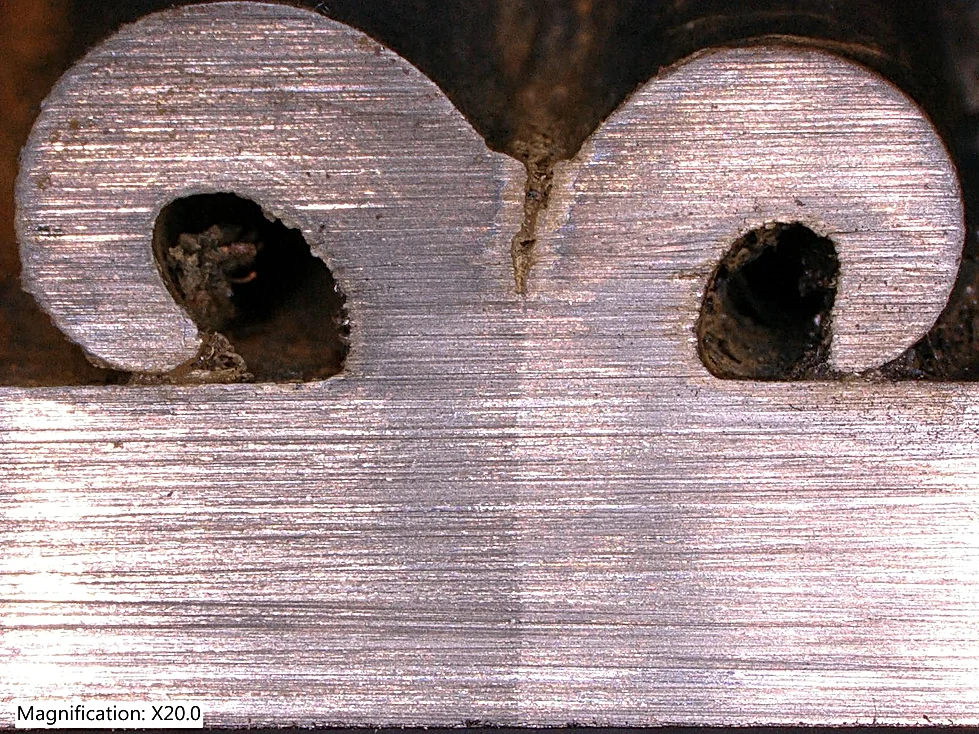

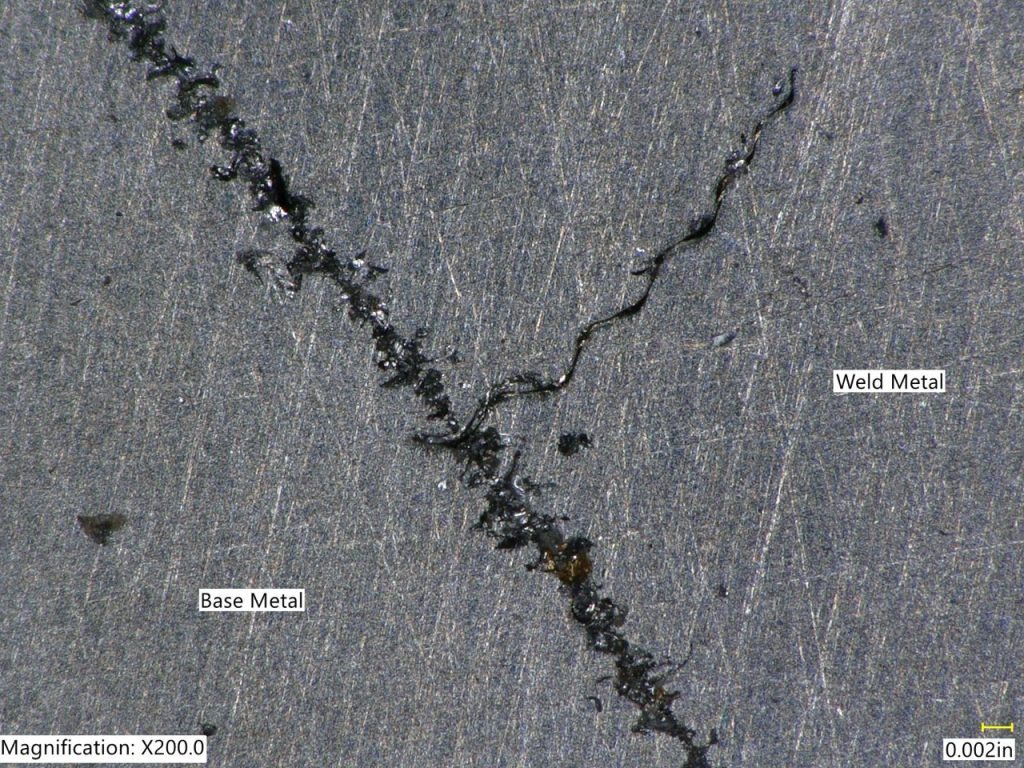

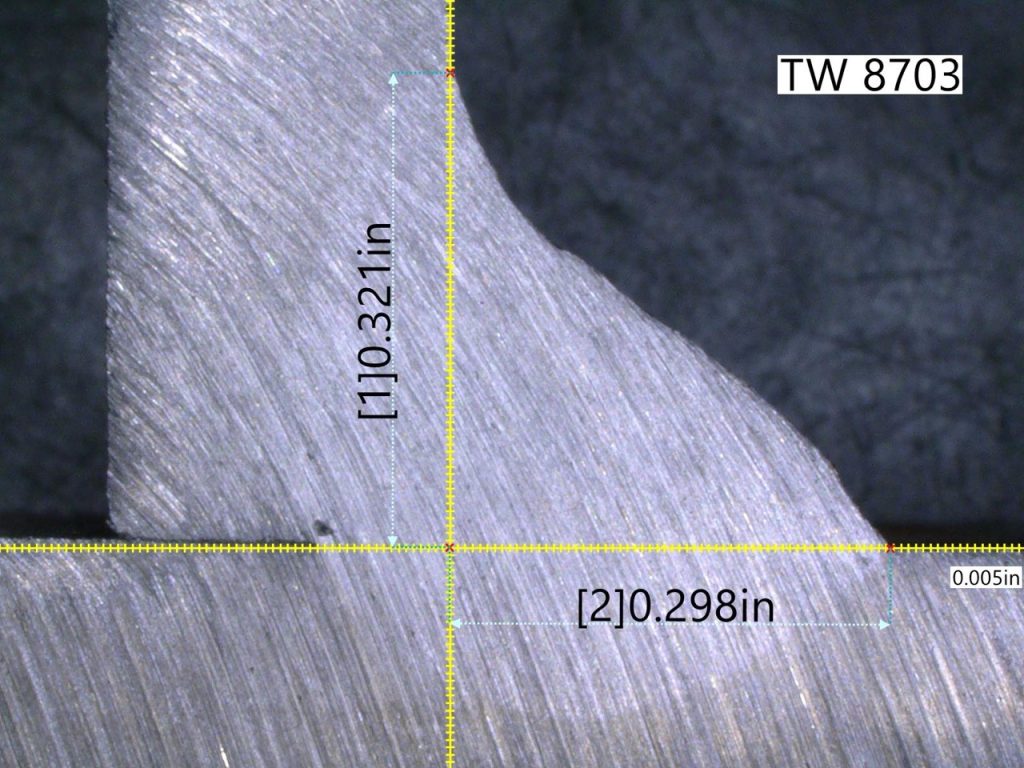

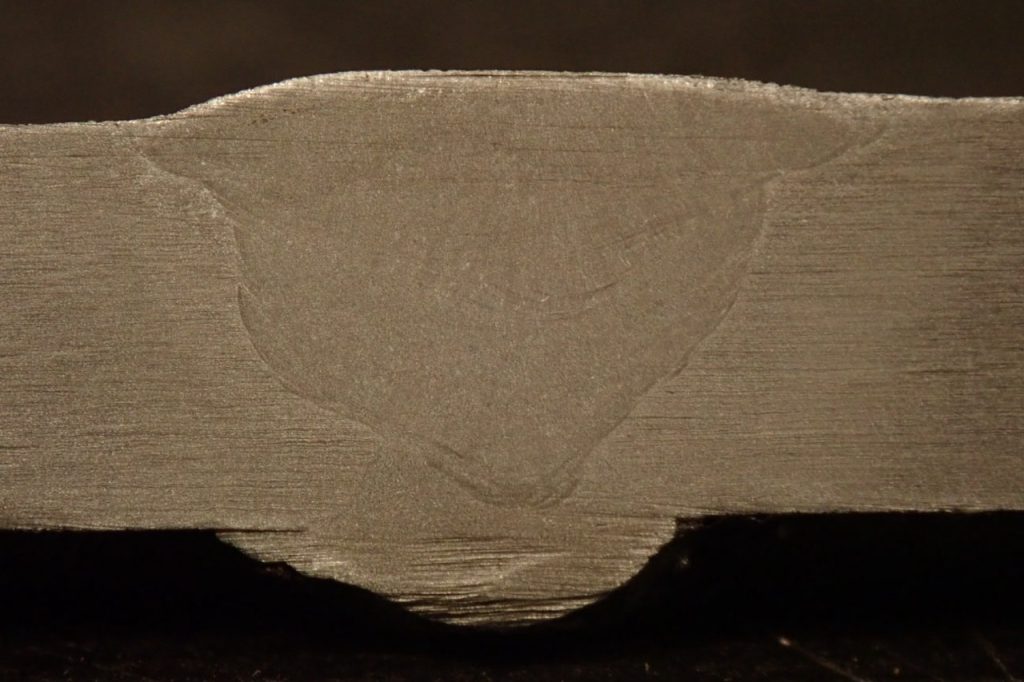

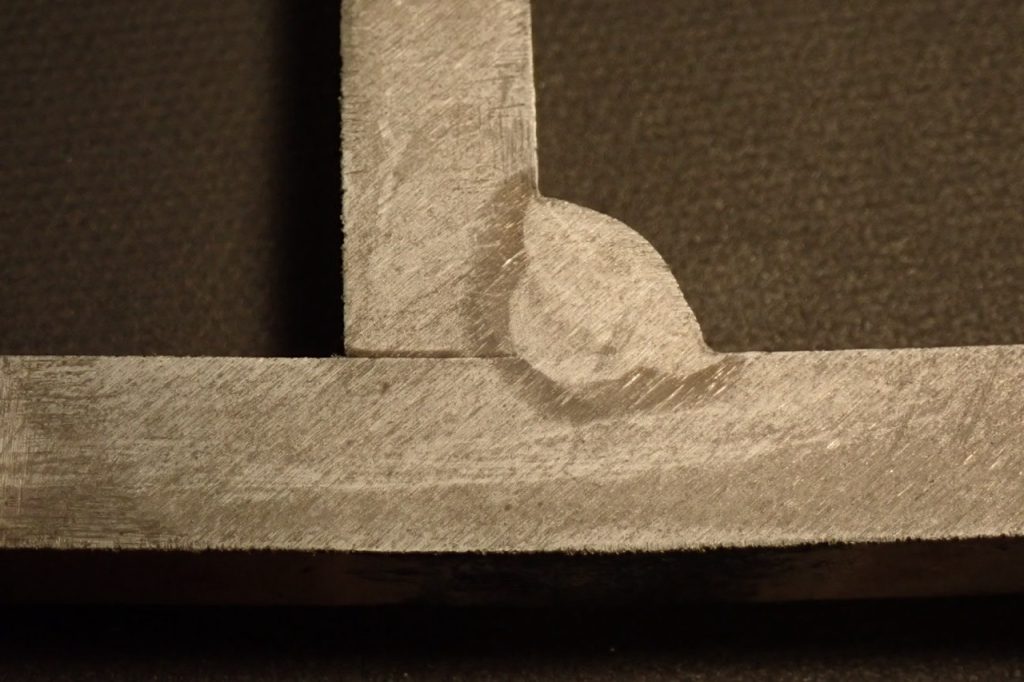

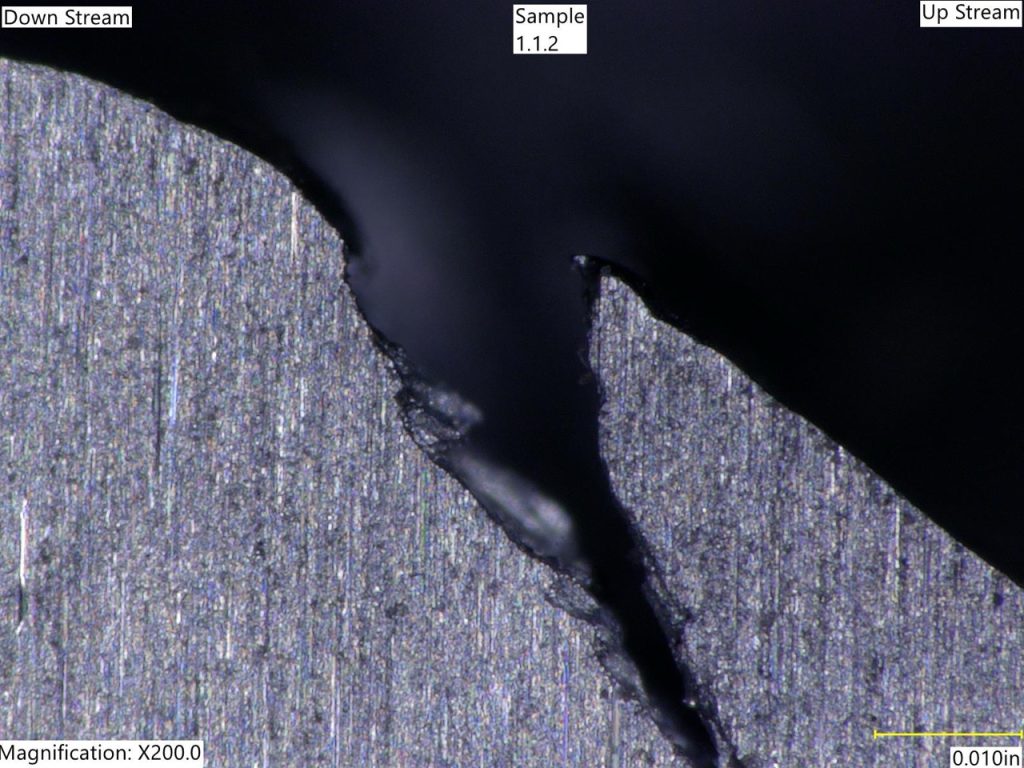

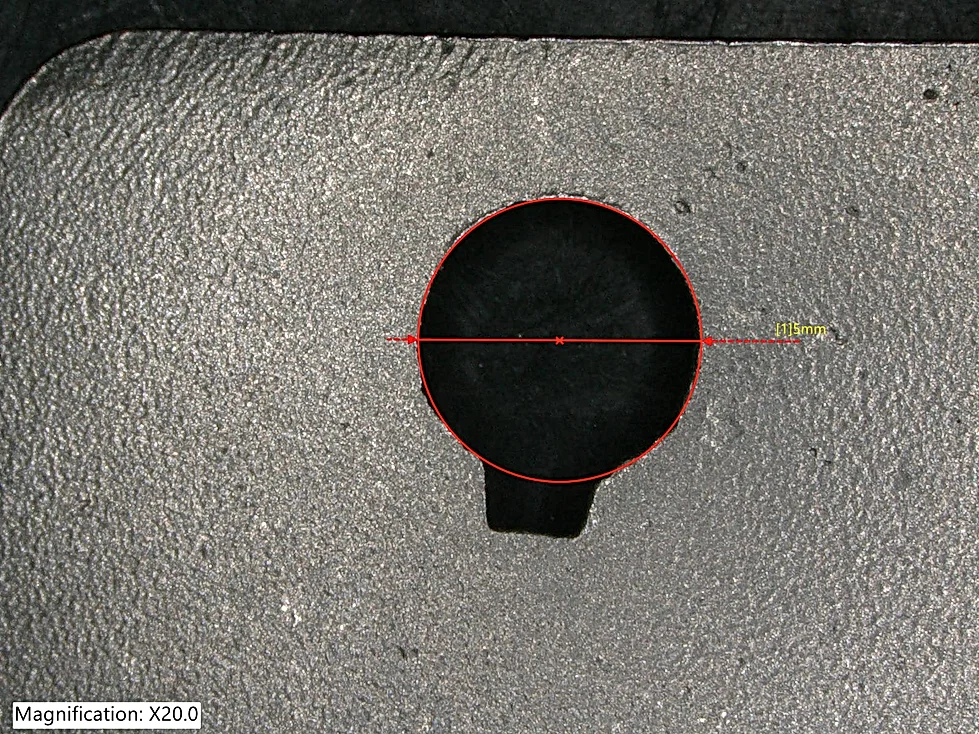

The Keyence microscope offers powerful magnification ranging from 20X up to 1,000X, enabling our experts to analyze microscopic details with exceptional depth and clarity. Whether we’re performing forensic weld investigations, analyzing failure surfaces, or inspecting metallurgical cross-sections, the Keyence 5000 gives us the ability to observe and document minute features that could be critical to understanding what went wrong—or what went right.

Advanced Imaging with the Keyence 5000

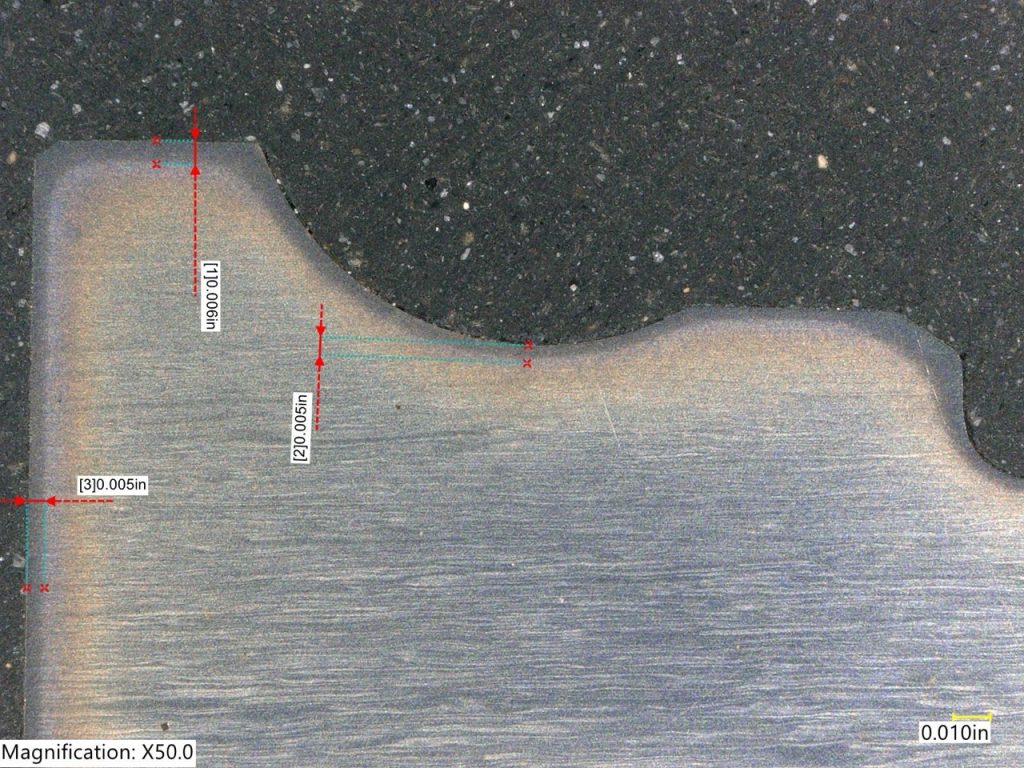

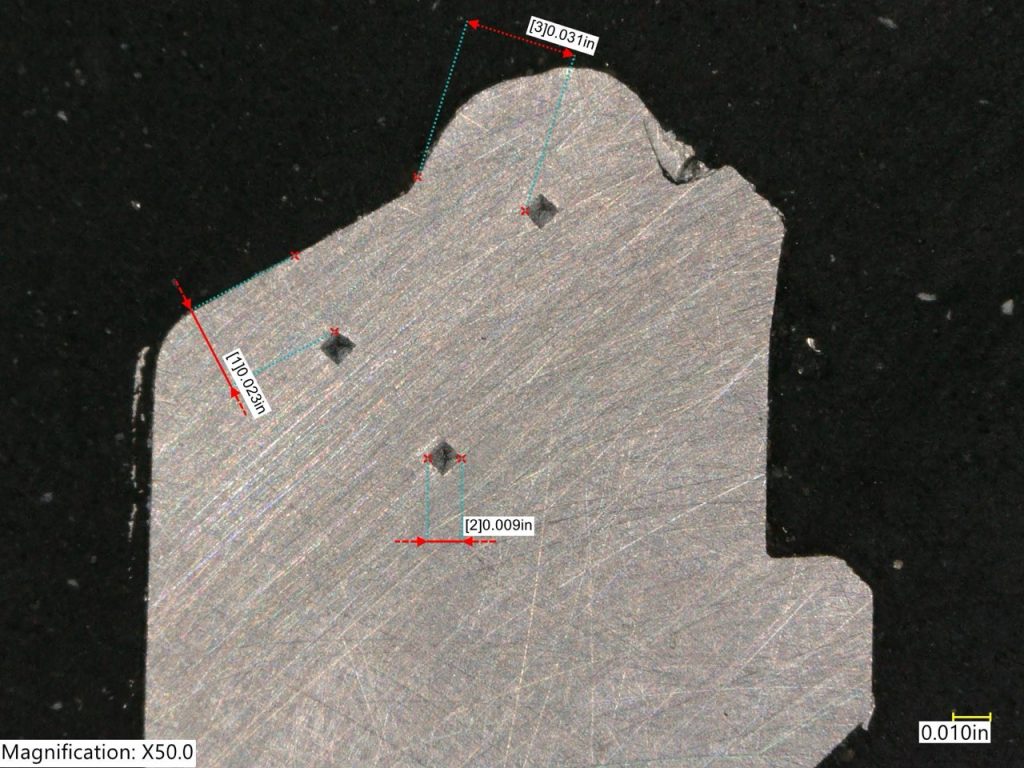

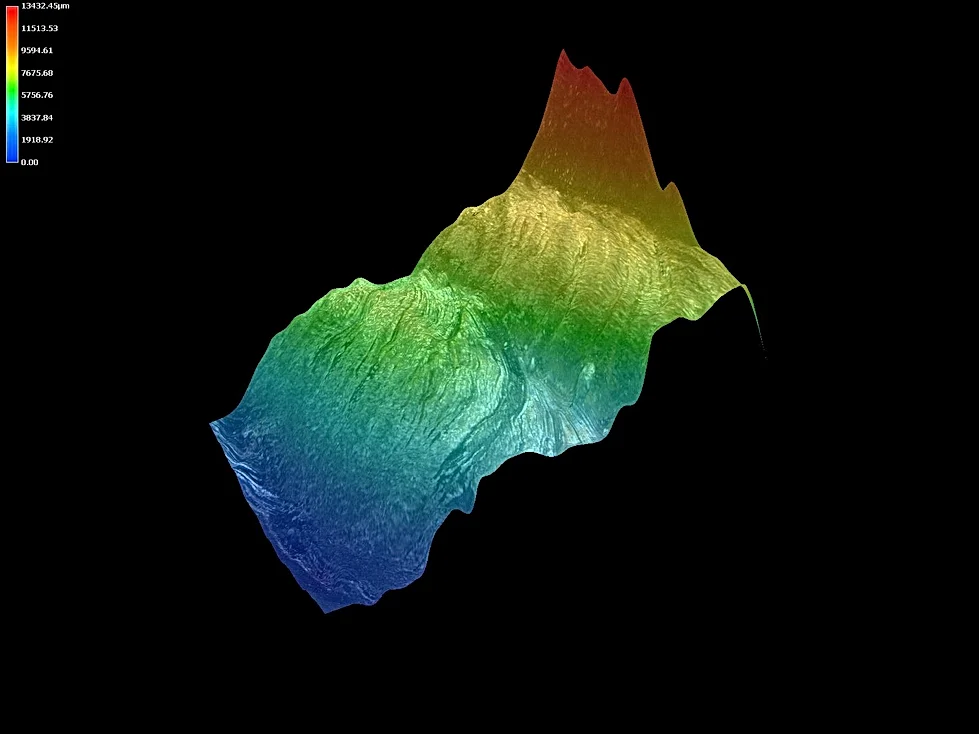

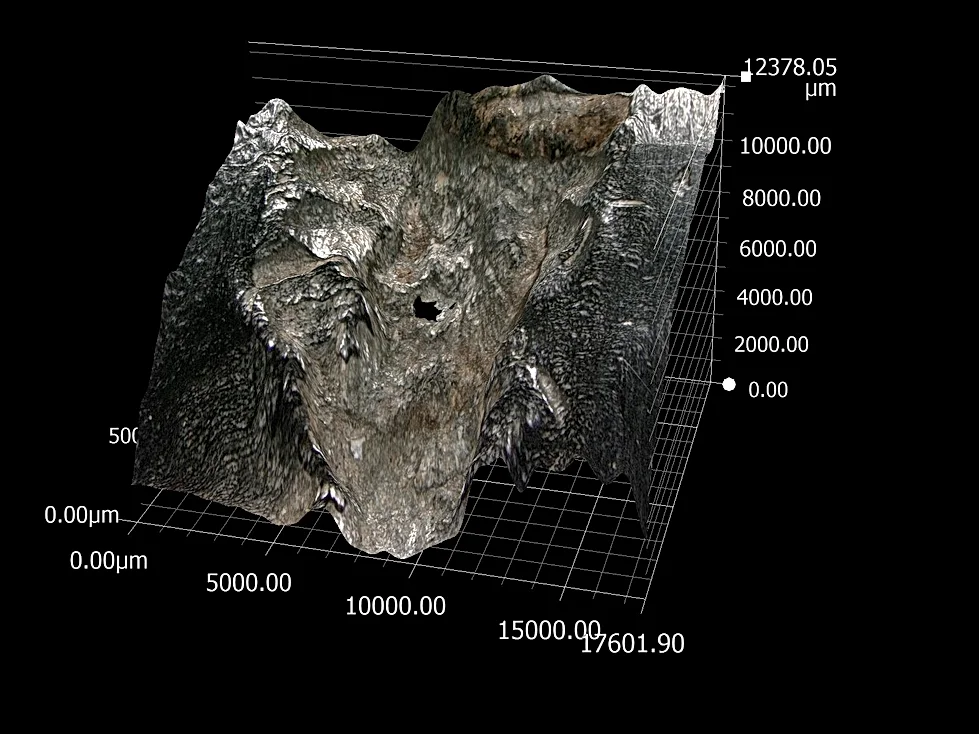

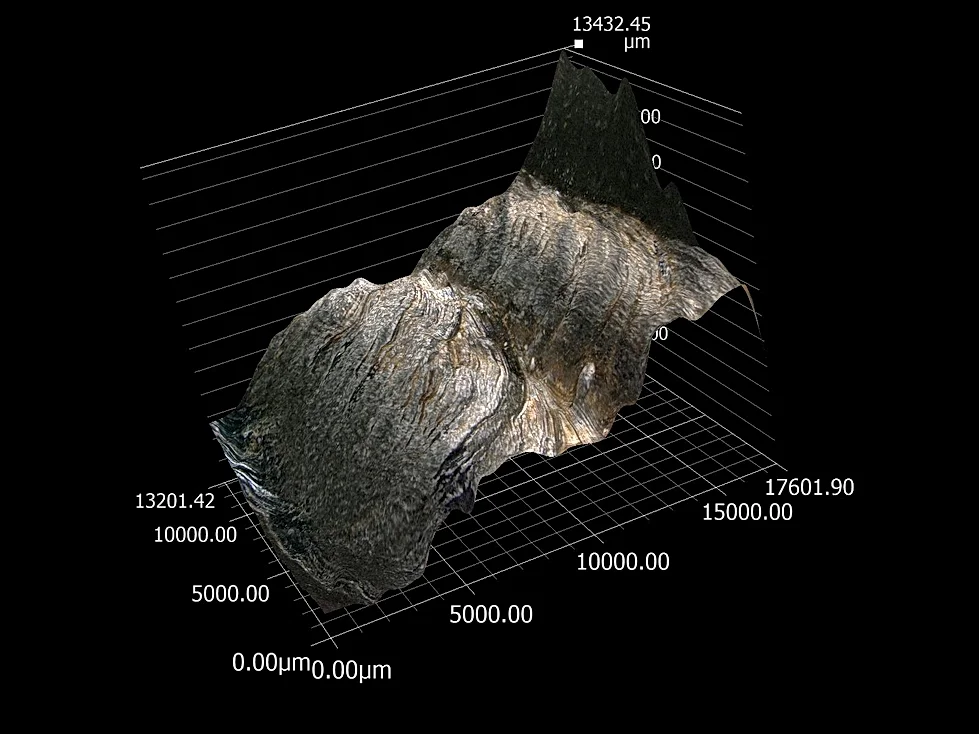

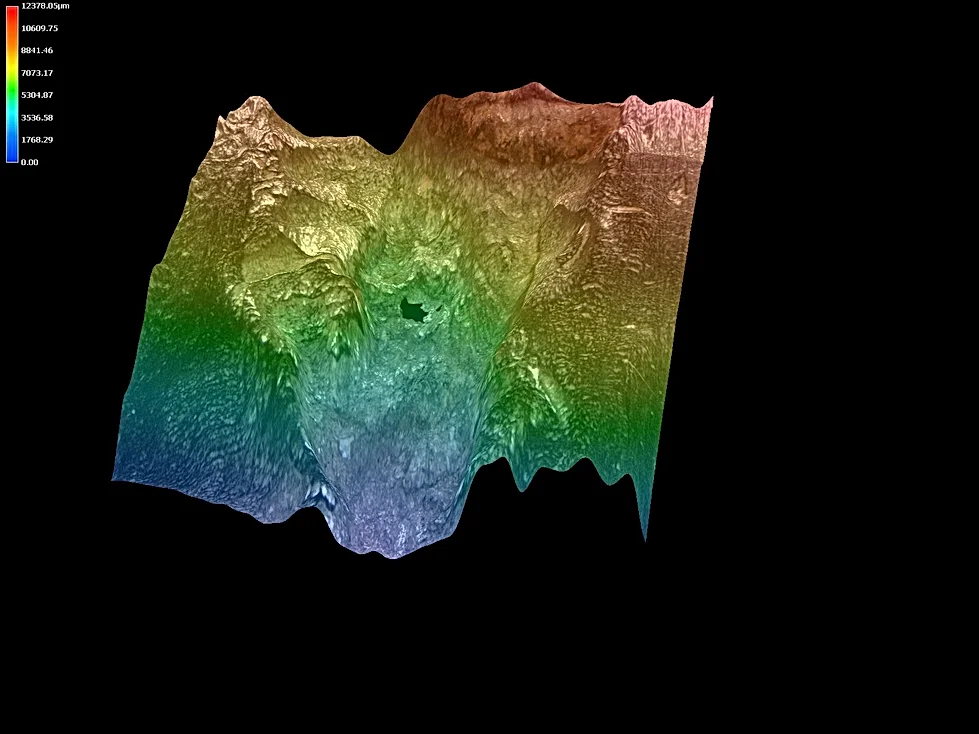

One of the standout features of the Keyence 5000 is its digitally controlled functionality. The microscope integrates the stage and lens information directly into its operation, creating a seamless workflow for capturing highly accurate images. The automatic stage moves up or down during image capture, determining the precise focus points of different areas within a sample. This allows the Keyence microscope to create 3D surface profiles with detailed height data, generating images that are not only visually informative but scientifically precise.

This 3D imaging capability is especially valuable for forensic and failure analysis, as it helps us understand the topography and surface characteristics of welds, fractures, and fatigue features. Unlike traditional microscopes, the Keyence 5000 uses the scale from the lens itself to provide measurements that are both two-dimensional and three-dimensional. This means our team can provide detailed, measurement-based assessments with confidence.

Why the Keyence Microscope Matters

In many forensic cases, the smallest detail can make the biggest difference. Whether it’s a crack initiation point in a failed weld, signs of improper heat treatment, or microscopic pitting from corrosion, having a tool like the Keyence microscope enhances our ability to identify and document these issues accurately.

Because the Keyence 5000 is engineered for both intuitive use and high-level accuracy, it supports our mission of making complex technical evaluations accessible and understandable. Clients from industries such as oil and gas, maritime, manufacturing, and construction trust WJMG to explain critical failures and confirm compliance with stringent standards. The Keyence 5000 helps us deliver those insights with precision and professionalism.

Applications Across Multiple Industries

At WJMG, the Keyence microscope is used in a variety of technical applications, including:

- Forensic investigations of weld and material failures

- Metallurgical examinations for contract compliance

- Surface inspection of materials subject to corrosion or fatigue

- Cross-section analysis of weld joints and heat-affected zones

- Documentation for expert witness testimony

With the Keyence 5000, we can digitally archive microscopic images for reports, legal cases, or engineering reviews. This ensures our findings are not only visual but verifiable and repeatable—crucial elements in both litigation and engineering assessments.

Trusted Expertise Backed by Leading Technology

Since 1978, WJMG has served as a trusted authority in welding consulting and failure analysis. Our commitment to using leading-edge tools like the Keyence microscope reflects our broader dedication to quality, innovation, and clarity. Whether we are preparing a technical report, supporting legal testimony, or consulting on process improvements, our team brings together decades of experience and cutting-edge equipment to serve our clients’ needs.

The Keyence 5000 is more than just a microscope—it’s a key part of our forensic toolbox, helping us uncover the truth, improve safety, and ensure compliance across multiple sectors.

If you’re in need of microscopic analysis, forensic documentation, or failure evaluation, contact WJMG today to learn how our Keyence microscope services can support your project.