Understanding Welding Microscopes: A Key Tool in Weld Inspection and Forensic Analysis

When it comes to ensuring the quality and safety of welding operations, precision is paramount. Whether it’s for routine inspection, failure analysis, or forensic investigations, welding microscopes are essential tools for professionals in the welding and metallurgical fields. At Welding & Joining Management Group (WJMG), we understand the importance of advanced imaging techniques, such as welding microscopes, in assessing weld integrity and uncovering critical details that might otherwise go unnoticed. In this blog, we’ll explore the role of welding microscopes in the industry, their capabilities, and how they help ensure high standards in welding applications.

What is a Welding Microscope?

A welding microscope is a specialized tool designed to provide detailed and magnified images of weld surfaces, structures, and defects. These microscopes are essential for performing high-precision inspections and analyses in welding metallurgy, forensic investigations, and failure analysis. Unlike traditional optical microscopes, welding microscopes often offer advanced features such as high magnification, digital imaging, and even 3D capabilities, making them invaluable for understanding intricate details in welding defects or metal fatigue.

Welding microscopes are used to inspect weld joints, weld defects, heat-affected zones, and the fine structures of welded materials. They play a crucial role in ensuring that welds meet industry standards and are free from defects that could compromise safety and performance.

The Role of Welding Microscopes in Weld Inspection

At WJMG, our expertise in welding and metallurgical consulting often relies on welding microscopes to conduct thorough inspections of welds. By using high-powered microscopes, we can examine the microstructure of welds and identify flaws such as cracks, porosity, and inclusions that may not be visible to the naked eye. These defects could potentially lead to failures in the future if left undetected.

Welding microscopes provide magnification levels that can reveal small irregularities in the weld pool, heat-affected zones, and base materials. This ability to scrutinize every detail is especially critical in industries where safety is the highest priority, such as oil, gas, and marine equipment, where WJMG often works to ensure compliance with stringent regulations.

Types of Welding Microscopes at WJMG

At WJMG, we use several advanced microscopes to analyze welds, each offering unique capabilities tailored to specific tasks:

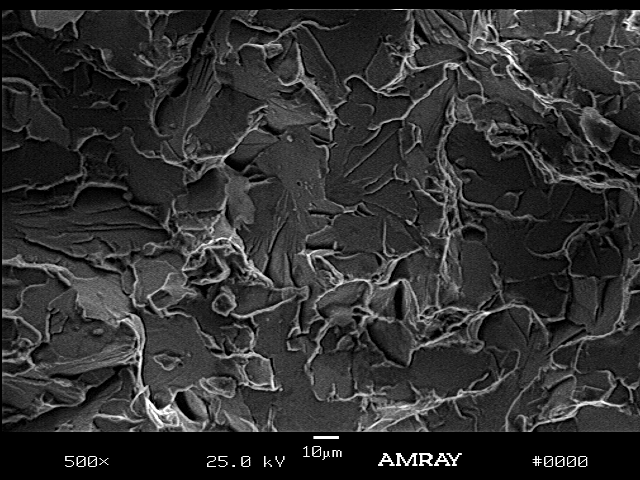

1. Amray 1830 Scanning Electron Microscope (SEM)

The Amray 1830 Scanning Electron Microscope is a powerful tool in our microscopy suite. With magnification capabilities up to 100,000X, it provides extremely detailed images of metallic surfaces, making it ideal for examining fracture samples and other irregular surfaces. This high-powered microscope is equipped with multiple detectors, including an energy dispersive X-ray (EDX) silicon drift detector, which helps identify the composition of materials at the microscopic level. This makes the SEM an invaluable asset for detailed failure analysis and understanding the root causes of weld failures.

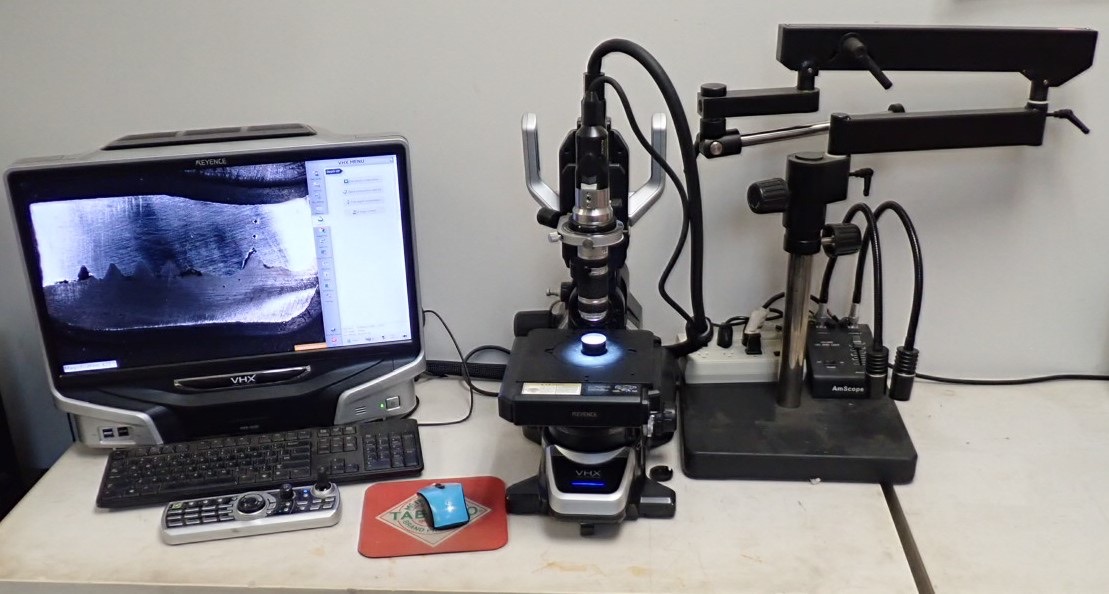

2. Keyence VHX-5000 Digital Microscope

The Keyence VHX-5000 Digital Microscope is a versatile, high-performance tool for capturing detailed images of surfaces at magnifications ranging from 20X to 1,000X. This microscope is equipped with an automated X-Y stage, which allows for large and small sample analysis with high precision. Additionally, the Keyence microscope features 3D imaging capabilities, enabling the examination of the depth of cracks, corrosion, and other surface defects. The ability to visualize depth is particularly useful in assessing the severity of damage or wear in welds, ensuring that any potential issues are identified early.

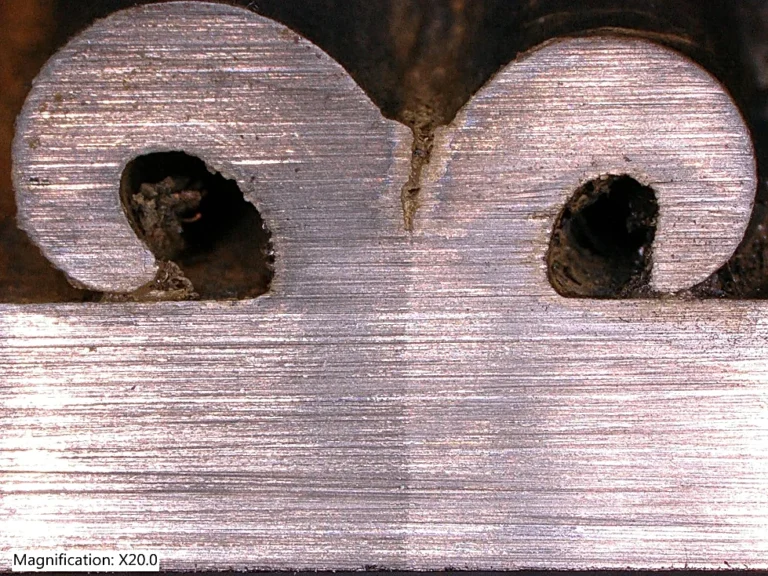

3. Stereo Microscopes

At WJMG, we also utilize stereo microscopes that provide magnification from 5X to 500X. These microscopes are perfect for capturing detailed images of surface defects, grain boundaries, and other features that may affect the performance of a weld. With their large X-Y stage, these microscopes allow for easy manipulation of samples, making them ideal for a wide range of sample sizes and welding applications.

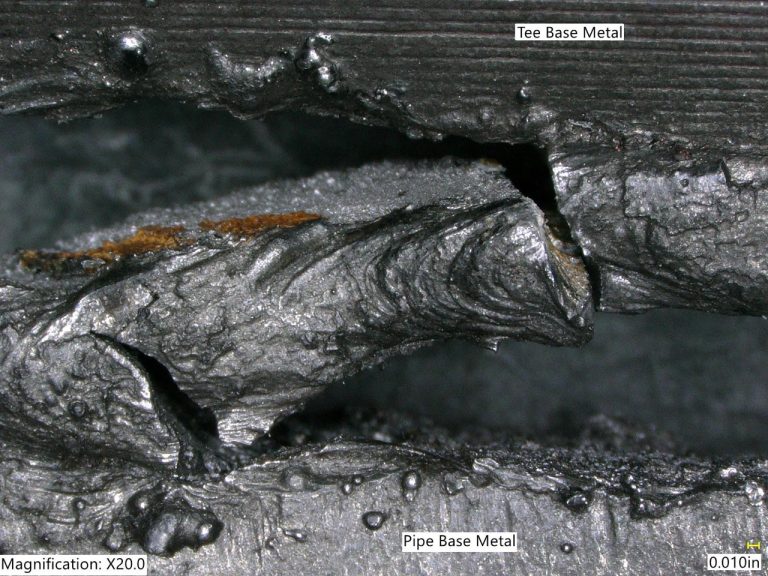

Why Welding Microscopes Are Crucial for Forensic Investigations

In forensic investigations, where the integrity of a weld is called into question, welding microscopes provide the level of detail necessary for accurate analysis. Whether investigating a failure in a critical component or analyzing the root cause of an accident, welding microscopes allow investigators to examine welds with the precision needed to identify defects that contributed to the failure.

At WJMG, our team of experts uses welding microscopes as part of our comprehensive forensic analysis services. Our Principal Investigator, with over 23 years of forensic analysis experience, relies on these tools to deliver accurate findings that are crucial for legal proceedings and regulatory compliance. Whether for litigation support or internal audits, welding microscopes help ensure that we provide clients with clear, actionable insights into welding quality and performance.

How Welding Microscopes Enhance Weld Quality Control

The use of welding microscopes extends beyond forensic analysis and into the realm of quality control. Regularly using welding microscopes for routine inspections helps to catch defects early, preventing them from becoming significant issues later. This is particularly important in industries with high-stakes operations, such as offshore drilling or aerospace, where a single flaw can have catastrophic consequences.

By identifying issues such as porosity, lack of fusion, or cold cracking during the inspection process, welding microscopes help companies maintain the highest standards of quality and reduce the risk of costly repairs or downtime. This proactive approach to quality control ultimately ensures the longevity and safety of welded structures.

The Critical Role of Welding Microscopes in Ensuring Weld Integrity

In the welding industry, the ability to inspect and analyze welds with precision is essential to ensuring quality, safety, and compliance. Welding microscopes, with their high magnification and advanced imaging capabilities, play an indispensable role in this process. At WJMG, we leverage cutting-edge welding microscopes such as the Amray 1830 Scanning Electron Microscope, Keyence VHX-5000 Digital Microscope, and Stereo Microscopes to provide in-depth analyses and forensic investigations, delivering accurate insights into the structural integrity of welded components.

Whether for routine weld inspection, failure analysis, or forensic investigations, welding microscopes help professionals maintain the highest standards of quality and safety. If you’re looking for expert welding consulting and advanced metallurgical testing, WJMG is your trusted partner in excellence.