Why Metallurgical Testing Matters: The Hidden Costs of Welding Non‑Compliance

When most people think about welding, they picture sparks flying and metal fusing under heat. But behind every weld lies something even more important: metallurgical testing. It’s not just about checking boxes for compliance—it’s about protecting your people, your assets, and your bottom line.

So, what happens when testing gets overlooked? Let’s take a closer look at how skipping metallurgical testing can cost you—and how proactive testing and expert consultation can save the day.

1. Foregoing Forensic Metals Testing Can Wreck Budgets

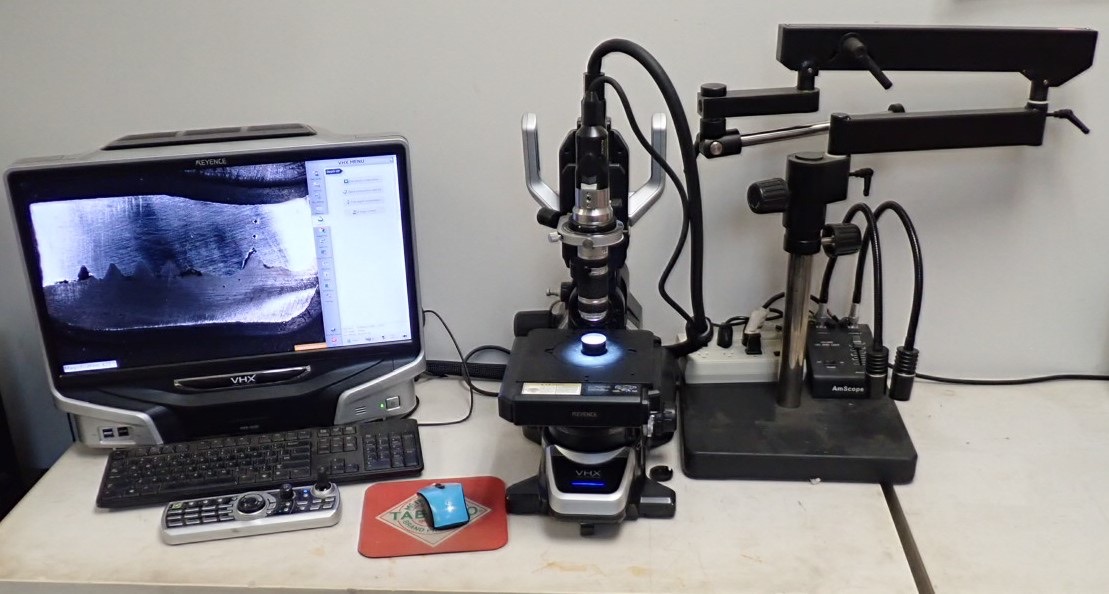

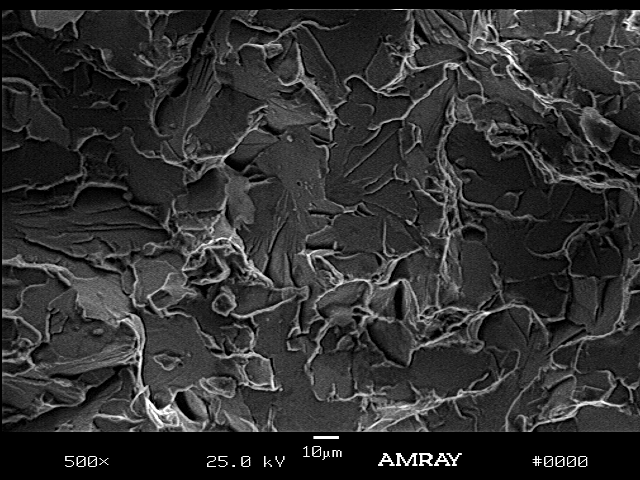

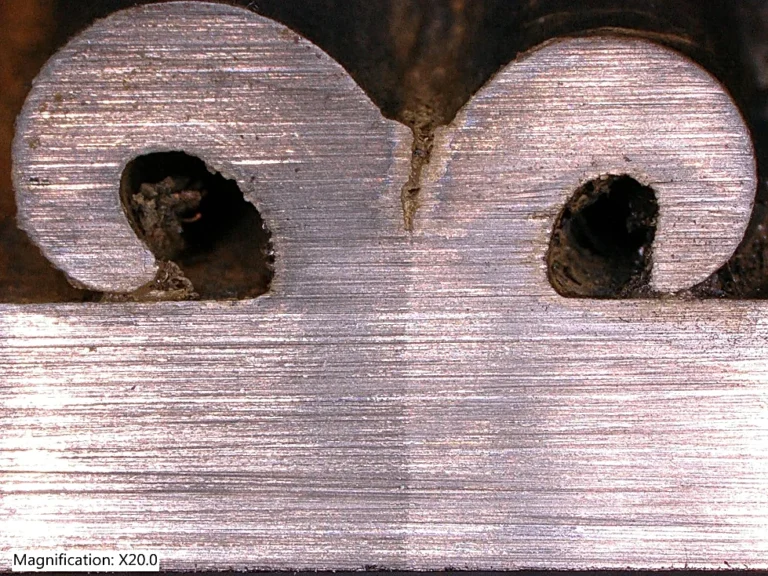

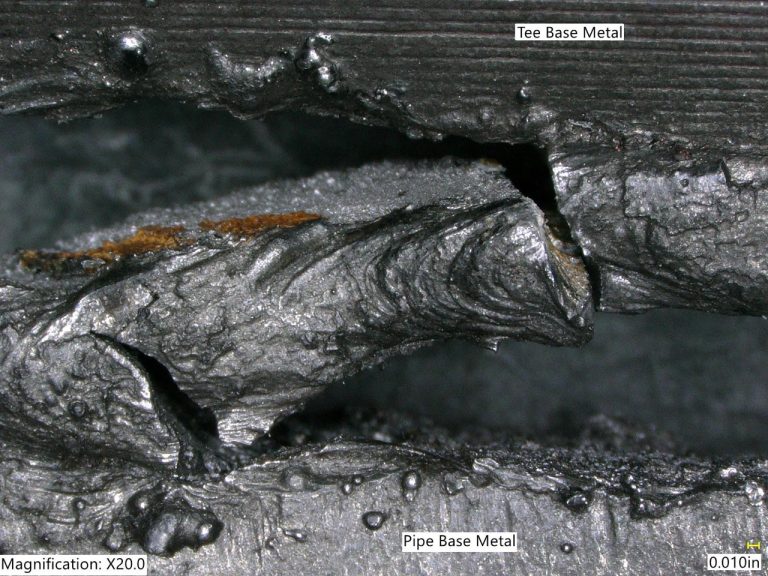

When a weld fails in service or inspection, forensic metals testing identifies why—examining failed components for cracks, porosity, or alloy mismatches. WJMG’s experts use SEM, Keyence microscopes, chemical analysis, and mechanical testing to pinpoint root causes. Without these insights, companies often repeat the same mistakes, doubling repair costs and risking extended shutdowns across oil & gas, marine, construction, and manufacturing sectors.

2. Welding Quality Supports Structural Integrity—and Compliance

Welds aren’t just aesthetic—they’re structural. Weak or non-compliant welds can trigger catastrophic failures in pressure vessels, pipelines, and infrastructure. By using metallurgical testing and expert weld assessments, you ensure that welding processes align with AWS, ASME, API, and USCG standards . Catching issues early—before cracks propagate—greatly reduces rework and extends asset life.

3. NDT Compliance Saves Time and Money

Non‐Destructive Testing (NDT) inspects welds without damage. WJMG offers ASNT Level III VT, MT, PT, UT, plus written practices compliant with SNT-TC-1A. These methods spot flaws at low cost—compared to the expense of tearing apart a failed component. Routine NDT is a small fraction of repair or replacement costs and ensures ongoing code compliance, reducing insurance premiums and liability risk.

4. Code Compliance: A Preventive Strategy

Compliance with codes—AWS D1.1, ASME IX, CFR 1910.252, API standards, etc.—isn’t bureaucratic red tape. It reflects decades of metallurgical lessons and structural failures. Metallurgical testing verifies that welds and materials meet spec, helping you avoid costly fines, project delays, and redesigns. In sectors like marine or energy, failing these checks can shut down projects completely.

5. Expert Testimony Minimizes Litigation Costs

When failures make it to court, expert witnesses specializing in metallurgical testing can build compelling cases. WJMG’s Dr. Jesse Grantham has testified in 100+ legal proceedings and shed light on multimillion-dollar welding disputes. If you’re a defendant, expert analysis often deflects liability; as a plaintiff, it substantiates your claim. Proactive metallurgical investigation before litigation gives you stronger defense—and often avoids court altogether.

When Should You Bring in Metallurgical Testing?

Understanding the value of metallurgical testing is one thing—but knowing when to use it is just as important. Here are key points in a project or lifecycle where metallurgical testing makes a measurable difference:

- During Design and Material Selection

Ensure chosen metals meet strength, durability, and environmental demands before fabrication begins. - Pre- and Post-Weld Inspection

Verify weld quality and code compliance to avoid structural failures and costly rework. - Scheduled Maintenance & NDT Programs

Catch early signs of fatigue, cracking, or corrosion before they escalate into major issues. - After Failures or in Legal Disputes

Use forensic testing and expert analysis to determine cause, assign liability, and support litigation or insurance claims.

By making this a regular part of your quality and compliance workflow—not just a reactive tool—you reduce risk, increase safety, and protect long-term asset performance.

Compliance Is the Best Insurance

If you’re building, fabricating, or repairing anything that involves metal, testing isn’t optional. It’s an essential part of doing business the right way—legally, safely, and intelligently.

WJMG has been helping companies across industries navigate these challenges for decades. With a full-service lab, expert consulting, NDT programs, and litigation support, they’re more than a testing partner—they’re your risk management ally.

Ready to protect your project and your reputation? Contact WJMG today and see how proactive testing can give you peace of mind—and real ROI.