WJMG Blog

WJMG Blog

-

NDT Written Practice: The Compliance Document That Protects Your Company

An NDT written practice is one of the most important documents supporting any nondestructive testing program. While it often sits behind the scenes, this document defines how inspection personnel are trained, qualified, certified, and evaluated. When one is missing, outdated, or poorly written, companies can face audit findings, rejected work, or serious challenges after a…

-

Hardness Testing for Welds: What It Indicates (and What It Doesn’t)

In welding and joining technology, hardness testing is one of the quickest ways to check how a weld and its heat affected zone reacted to heat input, cooling rate, and any heat treatment. It can flag areas that became unusually hard, confirm repeatability across multiple joints, and point you toward the right follow up test.…

-

Common Mistakes That Cause Welding Certification Test Failures — And How to Avoid Them

Achieving your welding certification can open doors in structural, pipe, aerospace and other welding environments. But many welders face setbacks when the test doesn’t go as planned. At WJMG, we believe understanding common pitfalls is key to turning your welding certification attempt into a success. Here are the typical mistakes we see — and how…

-

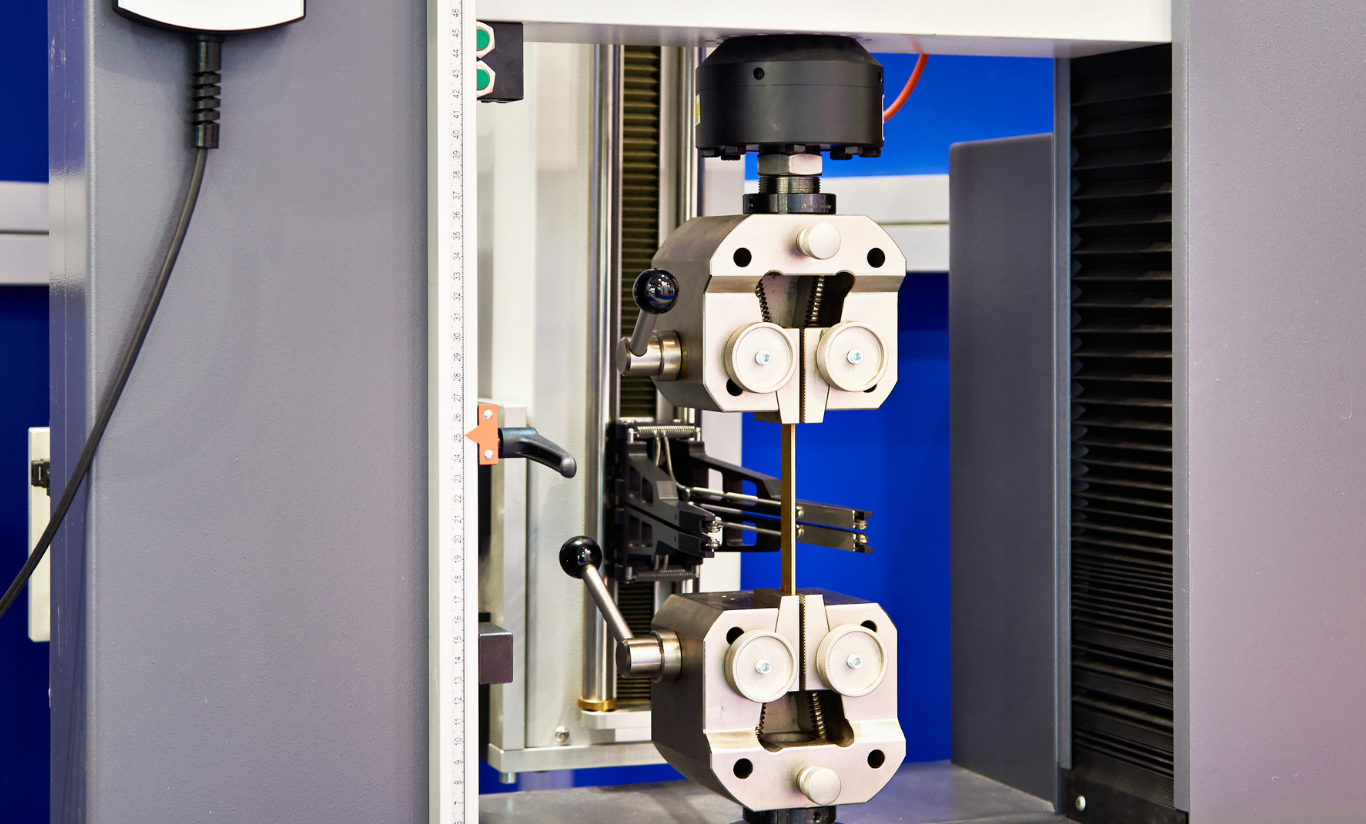

What Is Bolt Testing? A Comprehensive Overview

In the world of industrial quality assurance and structural integrity, bolt testing plays a pivotal role. At WJMG Forensic Metals Experts, every fastener is evaluated to ensure it performs under real-world demands. But what exactly is bolt testing, why does it matter, and how does it fit into a full mechanical and metallurgical testing program?…

-

Unlock Your Welding Career: Premier Welding Training in Denver

If you’re considering a career in welding or looking to advance your existing skills, welding training in Denver is one of the smartest investments you can make. Welding continues to be in high demand across Colorado and the nation, with industries ranging from construction and aerospace to energy and manufacturing seeking skilled and certified welders.…

-

Stress & Strain: When to Use Microhardness, Stress Relief, and Heat Treating in Mechanical Testing

In welding and fabrication, the quality of your finished product depends on more than just a clean weld bead. Beneath the surface, invisible stress, hardness variations, and microstructural changes can weaken performance. That’s where mechanical testing becomes essential. Mechanical testing methods like microhardness, post-weld heat treatment (PWHT), stress relief, and induction heating are used to…

-

Why Metallurgical Testing Matters: The Hidden Costs of Welding Non‑Compliance

When most people think about welding, they picture sparks flying and metal fusing under heat. But behind every weld lies something even more important: metallurgical testing. It’s not just about checking boxes for compliance—it’s about protecting your people, your assets, and your bottom line. So, what happens when testing gets overlooked? Let’s take a closer…

-

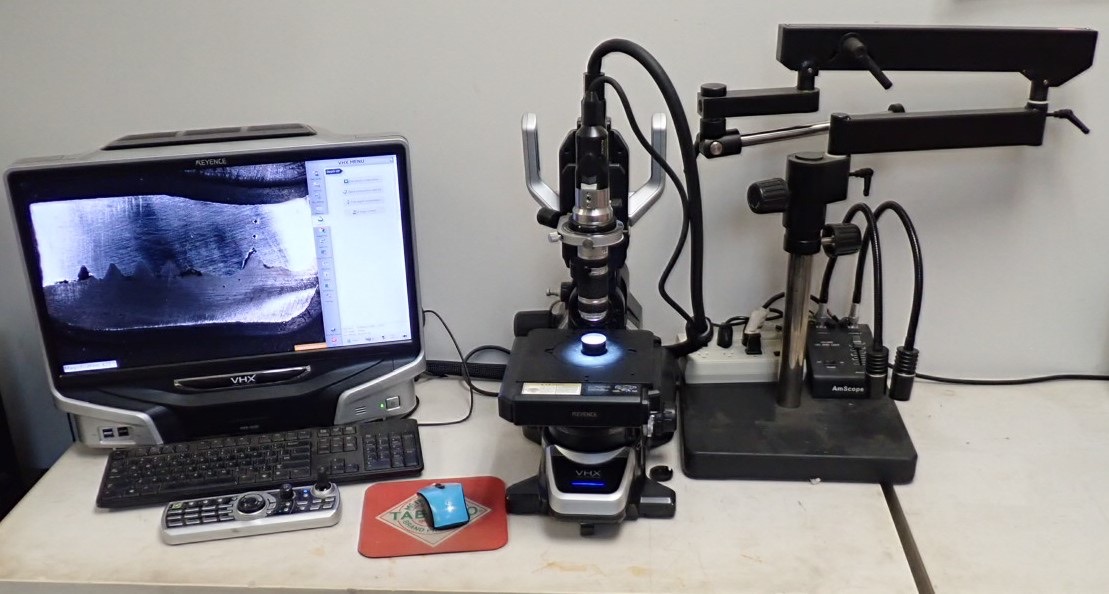

Understanding Welding Microscopes: A Key Tool in Weld Inspection and Forensic Analysis

When it comes to ensuring the quality and safety of welding operations, precision is paramount. Whether it’s for routine inspection, failure analysis, or forensic investigations, welding microscopes are essential tools for professionals in the welding and metallurgical fields. At Welding & Joining Management Group (WJMG), we understand the importance of advanced imaging techniques, such as…

-

What Is Forensic Welding

When welds fail, the consequences can be severe—leading to costly repairs, legal disputes, and even catastrophic structural failures. That’s where forensic welding comes in. This specialized field of metallurgy and engineering focuses on investigating and determining the causes behind weld and metal failures. Whether used in court cases or to improve future welding practices, forensic…