Stress & Strain: When to Use Microhardness, Stress Relief, and Heat Treating in Mechanical Testing

In welding and fabrication, the quality of your finished product depends on more than just a clean weld bead. Beneath the surface, invisible stress, hardness variations, and microstructural changes can weaken performance. That’s where mechanical testing becomes essential.

Mechanical testing methods like microhardness, post-weld heat treatment (PWHT), stress relief, and induction heating are used to verify weld integrity, prevent future failures, and meet industry standards. These techniques help ensure that parts function safely and predictably—whether they’re going into pressure vessels, pipelines, or structural frames.

Let’s break down what these testing processes are, why they matter, and how they work together to strengthen your welds and components.

What Is Microhardness Testing?

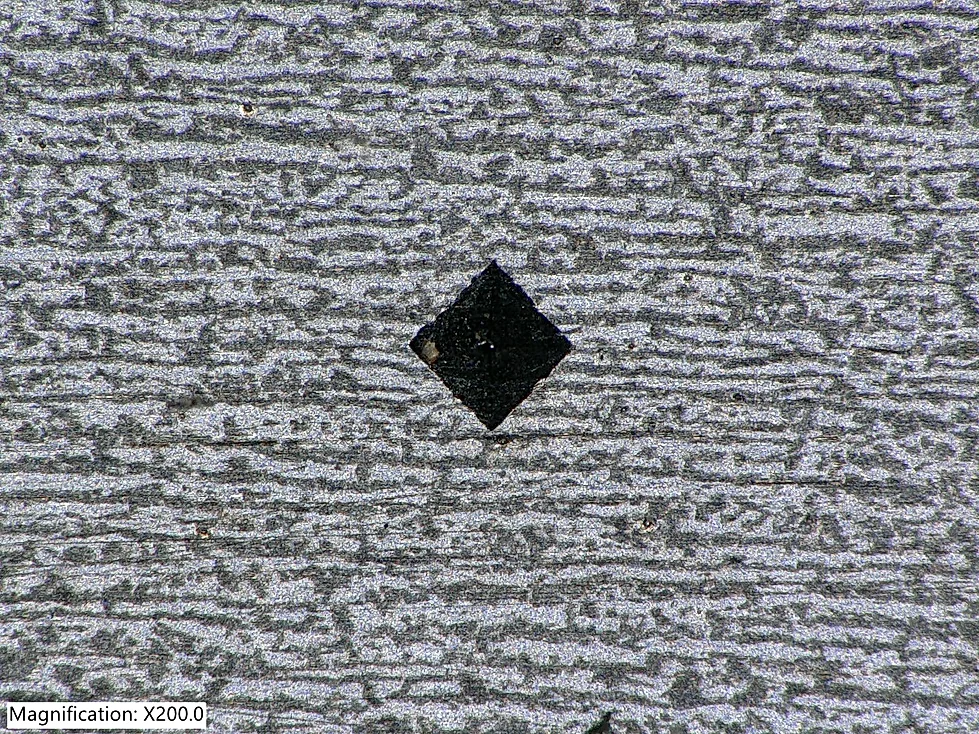

Microhardness testing is used to measure the hardness of very small areas of a material—typically across the weld metal, heat-affected zone (HAZ), and base metal. It’s especially useful when you need to see how welding or heat treatment has changed the material’s properties at a fine scale.

WJMG offers both Vickers and Knoop microhardness methods, which use precision diamond indenters and microscopic measurement tools to analyze the surface. This process helps identify:

- Soft spots that may lead to ductile failure

- Brittle zones that are vulnerable to cracking

- Inconsistencies across weld joints or heat-treated areas

By using microhardness testing before and after processes like heat treating or stress relief, engineers can confirm whether the part has been properly strengthened—or if further treatment is needed.

Post-Weld Heat Treatment (PWHT) and Stress Relief

After welding, metal structures often contain residual stress from the rapid heating and cooling process. These internal stresses can lead to cracking, warping, or even catastrophic failure over time—especially in parts that experience repeated loads or extreme conditions.

Post-weld heat treatment is a controlled heating process used to reduce these residual stresses. The component is gradually heated to a specific temperature, held for a set time, and then slowly cooled. This process relaxes stress, improves toughness, and restores ductility—making the material more stable and less prone to failure.

In addition to traditional furnace heat treatment, WJMG also offers vibratory stress relief using Metalax systems. This method uses mechanical vibrations to redistribute internal stresses without applying heat—ideal for large components that can’t be moved or heated easily.

When Is Induction Heating the Right Choice?

Induction heating provides a fast, localized way to apply heat to a component without using direct contact or an oven. Using electromagnetic fields, heat is generated directly in the metal itself—ideal for field work, on-site repairs, or when only a specific section of a weld needs treatment.

It’s commonly used for:

- Spot post-weld heat treating

- Preheating before welding to reduce thermal shock

- Surface hardening of high-wear areas

Because it’s efficient and precise, induction heating is often the go-to method for tight timelines or specialized applications where full heat treatment isn’t feasible.

When Should You Use These Mechanical Testing Techniques?

While every project is different, there are a few common scenarios where these mechanical testing processes are especially important:

- After welding critical components like pressure piping, tanks, or structural frames

- Before placing a part into service, especially in safety-sensitive environments

- During routine inspections for maintenance or quality assurance

- In failure investigations when you need to determine what went wrong and how to fix it

Mechanical testing gives you the insight to make informed decisions and ensures you meet all applicable industry codes, from ASME to API and AWS.

Building Confidence Through Mechanical Testing

If you’re in construction, energy, aerospace, or manufacturing, mechanical testing isn’t just about compliance—it’s about long-term performance. Microhardness testing helps you detect weaknesses, stress relief prevents failure, and heat treatment stabilizes your parts for the road ahead.

At WJMG, we offer a full suite of mechanical testing services both in the lab and in the field. Whether you’re welding new assemblies or investigating a material failure, our experts can help you reduce risk, meet regulatory standards, and protect your investment—one test at a time.