What Is Bolt Testing? A Comprehensive Overview

In the world of industrial quality assurance and structural integrity, bolt testing plays a pivotal role. At WJMG Forensic Metals Experts, every fastener is evaluated to ensure it performs under real-world demands. But what exactly is bolt testing, why does it matter, and how does it fit into a full mechanical and metallurgical testing program?

What Is Bolt Testing?

Bolt testing refers to the controlled evaluation of bolts and threaded fasteners to confirm that they meet specific performance and safety requirements. Rather than relying on manufacturer labels or specifications alone, bolt testing validates strength and compliance through engineered examination.

At WJMG, bolt testing is performed using tension or torque methods to confirm that each fastener meets the minimum required values for its intended application. These tests help ensure that bolted joints maintain integrity under stress, vibration, and load. By confirming the mechanical performance of each fastener, bolt testing provides confidence that a connection will function as designed.

Why It Matters

The importance of bolt testing cannot be overstated. Fasteners are the unsung heroes of construction, manufacturing, and heavy industry. When a bolt fails, the consequences can include costly downtime, damaged equipment, and serious safety hazards. By performing this testing before and after installation, engineers and facility managers gain confidence that each component meets load, stress, and environmental requirements.

From a compliance standpoint, bolt testing also helps companies meet ASTM, ISO, and ASME standards. For forensic investigations, it provides crucial insight into material defects, heat-treatment issues, or improper installation that may have contributed to a failure. WJMG’s expertise in mechanical and metallurgical testing ensures clients receive reliable results and actionable insights.

How Bolt Testing Fits Into Mechanical and Metallurgical Services

While bolt testing is a specialized process, it is closely integrated with other mechanical and metallurgical testing disciplines. In WJMG’s full-service laboratory, bolt testing often works in tandem with hardness testing, impact testing, metallographic examination, and failure analysis.

When a bolt is tested, our team may also evaluate its material microstructure, verify coating adhesion, or assess fracture surfaces to determine root cause. This holistic approach ensures that results are not only accurate but meaningful, connecting data to real-world performance and safety outcomes.

Common Methods Used in Bolt Testing

WJMG utilizes several industry-recognized methods to deliver comprehensive bolt evaluations:

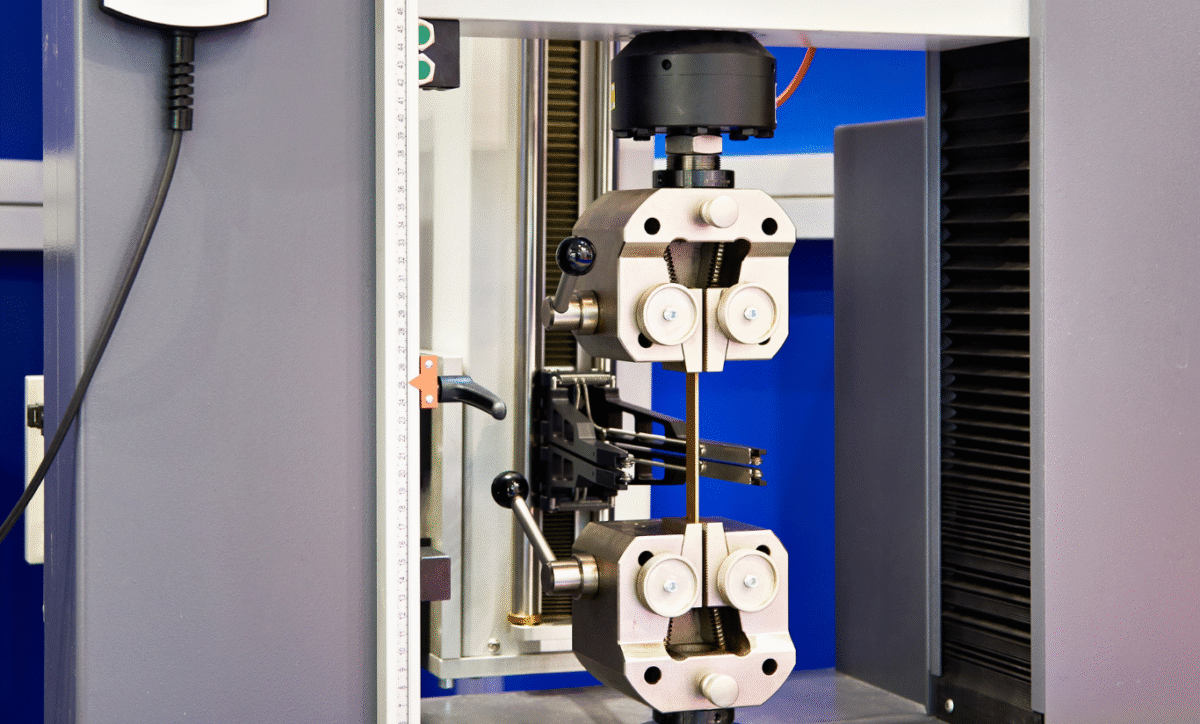

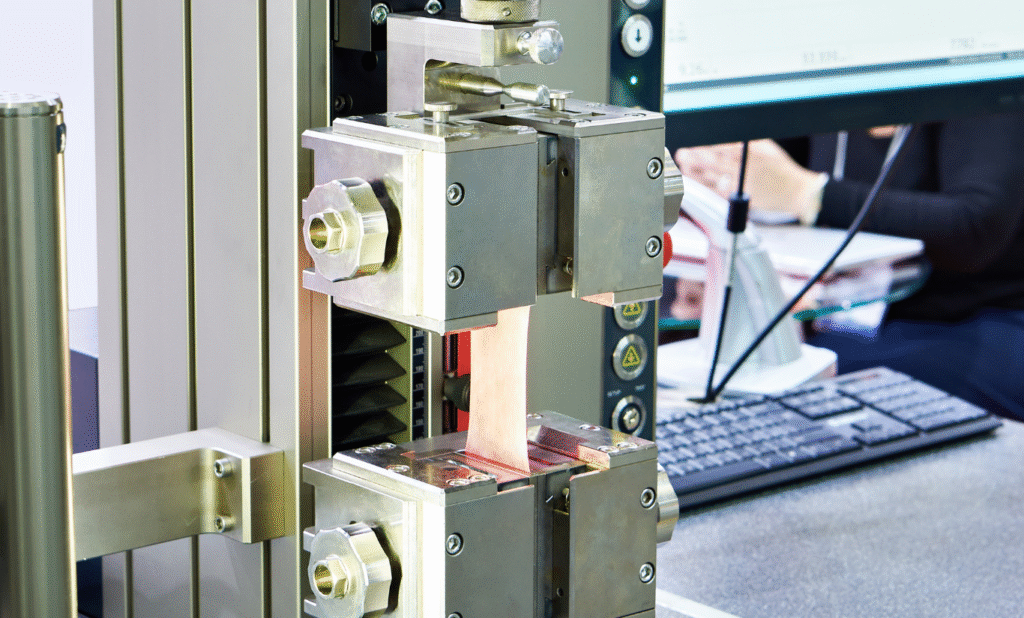

- Tensile Testing: Measures the ultimate tensile strength, yield strength, and elongation of a bolt by pulling it axially until failure. WJMG’s calibrated systems capture full stress-strain data to confirm material performance.

- Shear Testing: Evaluates a bolt’s ability to resist side-to-side forces in load-bearing applications. This test determines how a fastener behaves when forces act perpendicular to its axis.

- Torque Testing: Verifies that a bolt can achieve proper preload and clamping force without thread or head failure. Torque analysis is critical for ensuring long-term joint stability.

- Fatigue Testing: Simulates real-world cyclic loads to determine how a bolt performs over time. Many failures result from fatigue rather than a single overload event, making this test invaluable for preventive maintenance programs.

- Metallurgical Verification: Goes beyond mechanical data to confirm the bolt’s composition, heat treatment, and hardness profile. WJMG’s metallurgical experts use microscopic analysis and chemical testing to ensure every bolt meets its specification.

WJMG’s Approach

At WJMG Forensic Metals Experts, the testing process begins with understanding the client’s goals and application. Each test plan is customized based on the material, load conditions, and environment of use. All testing is performed with calibrated equipment and interpreted by skilled metallurgists and engineers who provide context and clarity, not just numbers.

Clients receive comprehensive reports that document the procedures, results, and conclusions. These insights help them make informed decisions about quality assurance, safety, and compliance.

Building Confidence Through Bolt Testing

In every industry where safety and reliability matter, bolt testing is an essential part of quality assurance. It helps prevent unexpected failures, supports compliance, and extends the life of critical assemblies. WJMG combines advanced testing capabilities with decades of metallurgical experience to give clients full confidence in their fasteners.

If you need to verify the integrity of your bolts or investigate a fastener failure, partner with WJMG Forensic Metals Experts. Our testing services provide the clarity and assurance your operation deserves.